China Factory High-temperature Alloy Nimonic Alloy 90

Description:

NIMONIC 90 (UNS N07090/W. Nr. 2.4632) is a wrought nickel-chromium-cobalt base alloy strengthened by additions of titanium and aluminum. It has been developed as an age-harden-able creep-resisting alloy for service at temperatures up to 920°C (1688°F. The alloy is used for turbine blades, discs, forgings, ring sections and hot-working tools.

Limiting Chemical Composition (%):

|

Carbon: 0.13 max |

Silicon: 1.0 max |

Copper: 0.2 max |

|

Iron: 1.5 max |

Manganese: 1.0 max |

Chromium: 18.0-21.0 |

|

Titanium: 2.0-3.0 |

Aluminum: 1.0-2.0 |

Cobalt: 15.0-21.0 |

|

Boron: 0.02 max |

Sulfur: 0.015 max |

Lead: 0.0020 max |

|

Zirconium: 0.15 max |

Nickel: Balance |

Applications:

The alloy is used for turbine blades, discs, forgings, ring sections and hot-working tools. Also used to make Aerospace fasteners.

Features:

1,High stress rupture strength and high creep resistance at high temperatures.

2,Good resistance to high-temperature corrosion and oxidation.

3,Age-hardenable.

4,High temperature dynamic applications

Forms Available:

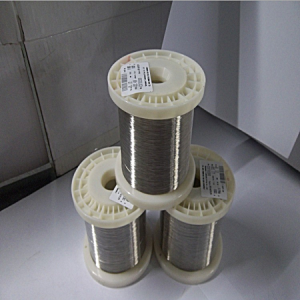

Plate, sheet, strip, bar, wire, rod, pipe, tube, forging.

Standards:

AMS 5829

Packing and Shipping